INJECTION MOLDING

Injection Molding

An Injection Molding Machine is used to manufacture plastic components by injecting molten plastic material into molds to form precise shapes. These machines offer high production efficiency, consistent quality, and accuracy, making them ideal for industries such as automotive, packaging, consumer goods, electronics, and industrial manufacturing. Injection molding machines help produce complex plastic parts in large volumes with minimal waste and reliable performance.

High Precious Industiral Vertical Injection Molding

Vertical injection molding

- A Horizontal Injection Molding Machine is widely used for manufacturing plastic components by injecting molten plastic into molds through a horizontally aligned clamping system. It is suitable for high-volume production and ensures consistent quality, efficient operation, and easy automation. Commonly used in automotive, packaging, household products, and industrial manufacturing, these machines deliver reliable performance and cost-effective production.

Key Features

Key Features of Injection Molding Machine

High production efficiency for mass manufacturing

Precise and consistent product quality

Ability to produce complex plastic components

Automated operation for reduced labor effort

Energy-efficient and cost-effective production

Suitable for a wide range of plastic materials

Minimal material wastage during production

Compatible with various mold designs and sizes

Available size

Size :

20 Gram to 500 Gram

Customization Support

Customization Support

Customization Support – Injection Molding Machine

Custom clamping force options as per production needs

Mold size and compatibility customization

Automation and robotic system integration

Material handling and feeding system options

Energy-efficient system configurations

Customized control panel and operating features

Machine size and production capacity adjustments

Special configurations for specific product applications

Application of Injection Molding Machine

Application of Injection Molding Machine

Applications of Injection Molding Machine

Automotive components

Packaging containers and caps

Household plastic products

Electrical and electronic parts

Medical and healthcare items

Consumer goods manufacturing

Industrial plastic components

Toys and molded plastic products

Why choose our Hot Sheet Press Machine!

- Designed for industrial-grade performance

- Custom-built solutions to match your production needs

- Reliable after-sales support and technical assistance

- Competitive pricing with high build quality

- Suitable for small, medium, and large-scale manufacturing units

Hot Sheet Press Machine

Technical Specification

| Parameter | Specification |

|---|---|

| Machine Type | Hot Sheet Press Machine |

| Pressing Area | 600 × 600 mm to 8 FT × 4 FT (Custom sizes available) |

| Pressing Capacity (Tonnage) | 20 Tons to 500 Tons (As per application) |

| Heating System | Electric Heaters (Optional: Thermal Oil / Steam Heating) |

| Maximum Temperature | Up to 300°C (Customizable) |

| Temperature Control | Digital PID Temperature Controller |

| Pressure System | Hydraulic |

| Hydraulic Pressure Range | Up to customer requirement |

| Platen Material | High-grade MS / EN Steel |

| Platen Heating | Uniform multi-zone heating |

| Platen Parallelism | High-precision guided structure |

| Frame Structure | Heavy-duty MS fabricated frame |

| Operation Mode | Manual / Semi-Automatic / Automatic |

| Power Supply | 380–415V, 50 Hz, 3 Phase (Custom voltage available) |

| Safety Features | Pressure relief valve, emergency stop, thermal protection |

| Control Panel | PLC / Relay-based (Optional PLC + HMI) |

| Surface Finish | Anti-corrosive industrial paint |

| Application Materials | Rubber, Plastic, Composite, Laminates, Panels |

| Customization | Size, tonnage, heating type, automation |

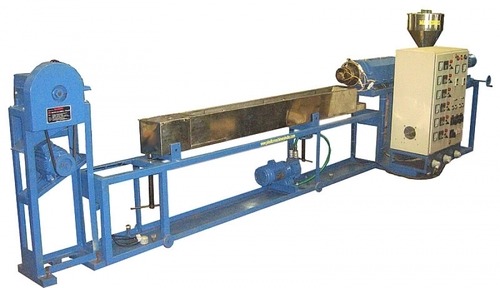

High Precious Industiral Horizontal Injection Molding

Horizontal Injection Molding

A Horizontal Injection Molding Machine is widely used for manufacturing plastic components by injecting molten plastic into molds through a horizontally aligned clamping system. It is suitable for high-volume production and ensures consistent quality, efficient operation, and easy automation. Commonly used in automotive, packaging, household products, and industrial manufacturing, these machines deliver reliable performance and cost-effective production.

Key Features

Key Features of Injection Molding Machine

High production efficiency for mass manufacturing

Precise and consistent product quality

Ability to produce complex plastic components

Automated operation for reduced labor effort

Energy-efficient and cost-effective production

Suitable for a wide range of plastic materials

Minimal material wastage during production

Compatible with various mold designs and sizes

Available size

Size :

20 Gram to 500 Gram

Customization Support

Customization Support

Customization Support – Injection Molding Machine

Custom clamping force options as per production needs

Mold size and compatibility customization

Automation and robotic system integration

Material handling and feeding system options

Energy-efficient system configurations

Customized control panel and operating features

Machine size and production capacity adjustments

Special configurations for specific product applications

Application of Injection Molding Machine

Application of Injection Molding Machine

Applications of Injection Molding Machine

Automotive components

Packaging containers and caps

Household plastic products

Electrical and electronic parts

Medical and healthcare items

Consumer goods manufacturing

Industrial plastic components

Toys and molded plastic products

Why choose our Hot Sheet Press Machine!

- Designed for industrial-grade performance

- Custom-built solutions to match your production needs

- Reliable after-sales support and technical assistance

- Competitive pricing with high build quality

- Suitable for small, medium, and large-scale manufacturing units

Hot Sheet Press Machine

Technical Specification

| Parameter | Specification |

|---|---|

| Machine Type | Hot Sheet Press Machine |

| Pressing Area | 600 × 600 mm to 8 FT × 4 FT (Custom sizes available) |

| Pressing Capacity (Tonnage) | 20 Tons to 500 Tons (As per application) |

| Heating System | Electric Heaters (Optional: Thermal Oil / Steam Heating) |

| Maximum Temperature | Up to 300°C (Customizable) |

| Temperature Control | Digital PID Temperature Controller |

| Pressure System | Hydraulic |

| Hydraulic Pressure Range | Up to customer requirement |

| Platen Material | High-grade MS / EN Steel |

| Platen Heating | Uniform multi-zone heating |

| Platen Parallelism | High-precision guided structure |

| Frame Structure | Heavy-duty MS fabricated frame |

| Operation Mode | Manual / Semi-Automatic / Automatic |

| Power Supply | 380–415V, 50 Hz, 3 Phase (Custom voltage available) |

| Safety Features | Pressure relief valve, emergency stop, thermal protection |

| Control Panel | PLC / Relay-based (Optional PLC + HMI) |

| Surface Finish | Anti-corrosive industrial paint |

| Application Materials | Rubber, Plastic, Composite, Laminates, Panels |

| Customization | Size, tonnage, heating type, automation |