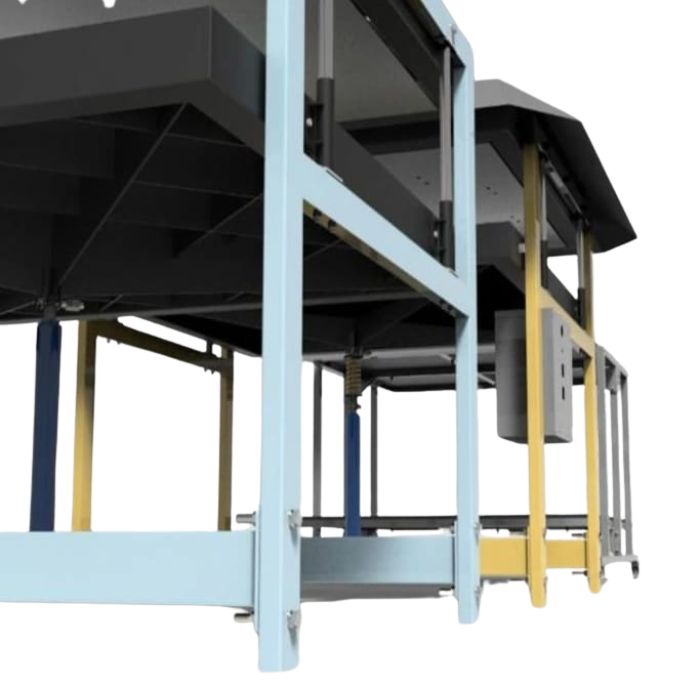

Manual Plastic Recycling Sheet Bending Machine 1500×1500 mm

Our 1500 x 1500 cm manual sheet press offers robust construction and precise operation, ideal for shaping various materials. Its user-friendly design ensures efficient performance, making it a valuable addition to your production line.

Applications:

Suitable for metal sheets, plastic sheets, and laminate compression.

A 1.5-meter hydraulic sheet press machine with hot press and cold press capabilities and a 10-ton, 8-jack system would typically have specific features to ensure efficient and precise operation. Here are some common features you will find in our machine:

Pressing Mechanism:

Hot Press System: Equipped with a heating system, such as electric, to heat the plates during the pressing process.

Cold Press System: Designed for ambient temperature pressing without the need for additional heating elements.

Product Details

Key Features:

• Capacity Range: 20 to 400 tons (customizable to your needs)

• Pressing Area: 150 X 150 CM for medium-sized sheets

• Manual Operation: Simple and easy-to-use handling

• Durable Construction: Heavy-duty materials for long-term performance

• Customizable Design: Tailored settings for specific production needs

Why Choose Our 150 X 150 CM Sheet Press Manual?

• Cost-effective solution for manual sheet pressing

• Ideal for medium-scale production tasks

• Customizable for different materials and pressures

Hydraulic System:

10-Ton Capacity: The hydraulic system is capable of exerting a force of 10 tons to press the sheet materials.

8-Jack System: Eight hydraulic jacks distribute the pressing force evenly across the sheet material.

Control Panel:

User Interface: A control panel with an intuitive user interface to set parameters such as pressure, temperature (for hot press)

Temperature Control (for hot press): If the machine includes a hot press system, it would have temperature controls for precise heating.

Safety Features:

Emergency Stop: An emergency stop button for immediate halting of the machine in case of any issues.

Safety Guards: Protective guards to prevent operators from coming into contact with moving parts during operation.

Pressing Area:

The machine is designed to handle sheets up to 1.4 meters in length and width.

Platen Surfaces:

Smooth and Flat: The platen surfaces (the pressing plates) are typically smooth and flat to ensure an even distribution of pressure across the sheet.

Materials Compatibility:

Suitable for Various Materials: The machine is designed to work with a variety of plastic waste like HDPE, LDPE, PP, PS, ABS, etc…

Cycle Time:

Adjustable Pressing Time: The machine allows users to set the duration of the pressing cycle, which may vary based on the type and thickness of the material.

Frame Construction:

Sturdy Construction: The frame is constructed from durable materials to provide stability during operation.

Cooling System (for hot press):

If the machine is equipped with a hot press system, it may include a cooling system to quickly reduce the temperature of the platens after pressing.

Maintenance Features:

Accessibility: Easy access to components for maintenance and cleaning purposes.

Footprint:

Compact Design: The machine is designed to occupy a reasonable floor space while still accommodating 1-meter-wide sheets.

Power Supply:

Electrical Requirements: 3 Phase 380V/415V 30KW 50/60HZ

[title text=”Frequently Asked Questions”

Related products

-

SHEET PRESS

Cold Press Manual Sheet Press Machine

-

SHEET PRESS

Manual Sheet Metal Bending Machine 100 MM